Modular construction

[arrow-down]Traditional construction is no longer the only option today. Investors who want to shorten the construction time choose modular construction. But a short construction period is not the only benefit. Are you considering using modular technology for your project? Find out what the modular system is and what advantages it offers.

Modular construction - what characterises it?

Although modular construction in Poland is not new, the scale of construction using this technology is still small. Hence, the question of what is modular construction often arises. As the name suggests, modular construction is based on the use of modules. Unihouse modules can vary in size and equipment. The fact that they can be manufactured all year round eliminates the seasonal downtime that occurs with traditional construction. Production under controlled conditions and using partial automation also minimises errors.

Building modules are lightweight structures, so they can be transported from the factory to the construction site without much difficulty. But that's not all - they are also:

- adapted to modern requirements and standards - Unihouseweb's modular construction uses environmentally friendly materials and features good sound insulation;

- fire-resistant - the basic building material for the building modules is wood, which is properly protected at the production stage;

- energy-efficient - thanks to the use of heat-insulating materials, the energy requirement is minimal, which means that modular housing is cheap to operate;

- repetitive - this is important when modular hotels or multi-family buildings, for example, are built from them;

- universal - the manufacturer of modular buildings Unihouse offers buildings fully adapted to the needs of investors in terms of, for example, the number of storeys, the area of rooms or the architectural form.

The administrator of your personal data is the company UNIHOUSE S.A., ul. Rejonowa 5, 17-100 Bielsk Podlaski.

-

> 20 LAT

industry experience

-

4876

flats built

-

24H/7

advice and support to the sales department

-

Short construction lead times

As a result of transferring part of the technological processes from the construction site to the production hall, e.g. turnkey construction of a hotel in 3-4 months (depending on the design assumptions) -

Complexity from design to turnkey

Possibility to design your own idea, build and erect the modules on site, hand over the flats ready to move in -

Attractive price

in line with quality -

Modern technology

using the advantages of environmentally friendly materials such as wood, gypsum, mineral wool -

Attractive designs

Can be customised or built to customer's design -

Can be extended and implemented

at any location, simple assembly, disassembly and relocation -

Certified quality and complete fire protection building elements to fire resistance level REI 60

-

Favourable and user-friendly microclimate

interiors of houses and buildings thanks to the use of natural materials -

Saving on running costs

thanks to excellent thermal insulation of walls and roofs (U< 0.18 W/m2K), low energy consumption for heating the house/building 40-70 kWh/m2/year - low operating costs -

Sound insulation

of intermediate walls 63 dB -

Security of cooperation

Partner with a stable market position -

Production under controlled factory conditions

independent of weather conditions and assembly under any weather conditions

Short investment times - modular buildings

It is no coincidence that modular construction is often referred to as 'rapid construction'. The building ordered by the investor can be constructed in just a few months, which is much quicker than buildings erected using traditional methods. The final completion time depends on the size of the building. Unihouse's crèches and modular schools are good examples - the lead time for such developments is around 6 months. At the same time, the modules can even be combined during the winter, if the ground has been prepared in advance. The foundations - like basements or underground garages - must be constructed using traditional technology.

The term rapid modular construction does not only refer to new construction - it is just as fast:

- extend the facility with additional modules - this is especially important for public facilities;

- dismantle selected modules - if the usable area of the facility is too large;

- relocate part or all of the facility - if necessary.

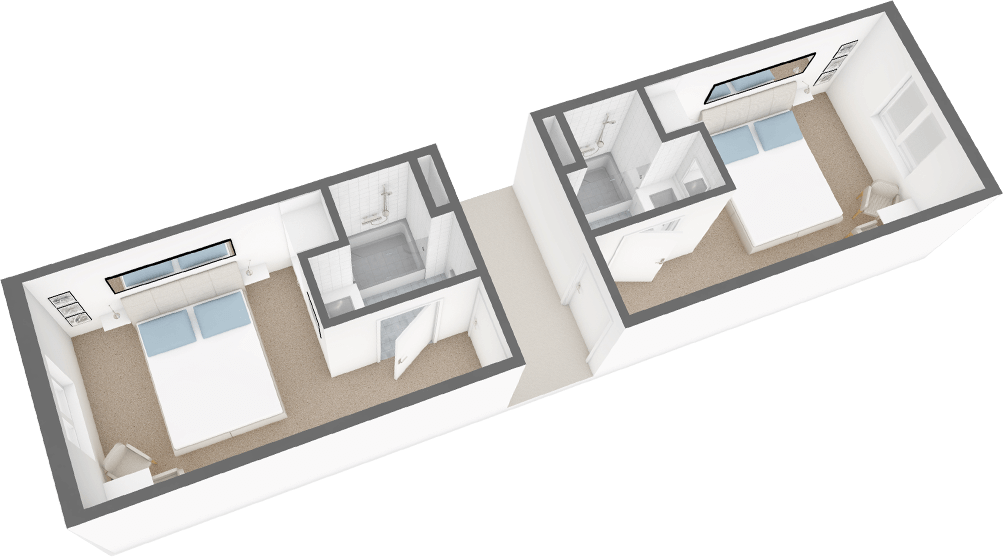

Typical module

Modern modular housing on offer from Unihouse!

Modular technology is increasingly being chosen by developers - this is evidenced by new housing developments not only in Poland, but also in other European countries. However, modern modular construction with a timber frame is not only about modular multifamily buildings - the advantages of this innovative technology are also recognised by universities, municipalities, companies in the tourism industry and services such as the police or the army, among others.

Modular buildings, thanks to their unique characteristics, are perfect for schools, outposts, dormitories or care centres - investors appreciate not only the low cost of ownership, but also the high quality of finish, durability and safety. Would you like to find out more about the benefits that building modules offer? Are you interested in their price? Contact us and we will introduce you to the possibilities of ecological and modern modular construction.

Examples of projects

Modular construction - FAQ

-

What is modular technology?

Modular technology - building construction technology based on prefabricated modules, i.e. spatial, three-dimensional (volumetric) segments. They can have a varied load-bearing structure, i.e. timber frame, solid wood, steel, concrete, hybrid. Modules are characterised by a high degree of prefabrication. They are manufactured as factory-finished structural elements that are delivered to site and assembled as large volume elements or as essential building components such as whole rooms, parts of rooms or separate units with a high level of utility. On-site finishing work consists of activities related to the connection of modules and their components such as installations. Alternatively, they may include the execution of works whose technology precludes completion on site.

-

What is a module and what are its characteristics?

Modules in modular construction are innovative, prefabricated segments that are revolutionising the construction process. They are self-contained construction units that can be quickly and efficiently assembled on site to create durable and aesthetically pleasing buildings. Thanks to their repetition and manufacture in the factory, modules ensure short lead times, reduced costs and reduced risk of errors.

-

What can be built from modules?

The use of modules makes it possible to build a wide range of facilities, from educational to commercial. A wide variety of buildings can be built from modules, such as schools, nurseries, kindergartens, dormitories, public buildings, office buildings, as well as healthcare facilities, sanatoriums or hotels, military facilities. Modular construction is distinguished by its short construction time, energy efficiency and minimised environmental impact, making it an attractive choice in terms of sustainability. See: Unihouse realisations.

-

How high can you build with Unihouse modules

Unihouse has built eight-storey modular buildings, including the Heimdalsporten project in Trondheim, Norway. It is technologically possible to build higher, but as the height increases, so do the fire protection requirements, which are costly. The financial viability of such a project must be determined on a case-by-case basis.

-

How fast is construction from modules?

The lead time for modular construction depends on many factors, such as the complexity of the project, its size and specific requirements. Unihouse adapts the production and assembly schedule to the individual needs of each project. With prefabrication, Unihouse cuts construction time by up to half, compared to traditional methods. Structural components are manufactured in the factory, allowing rapid assembly on site. For a specific project, it is possible to obtain a timetable from Unihouse for the completion of the project.

-

Are modular buildings sustainable?

Timber modular buildings are durable and can be compared to masonry buildings in terms of durability. The ETA certificate includes a lifespan of 50 years, which is the standard lifespan for permanent buildings regardless of the type of construction technology. Thanks to the use of suitable solutions and high-quality materials, timber frame structures are resistant to negative external influences. In addition, modular buildings are energy-efficient and have better thermal insulation than traditional brick houses.

-

Is modular construction cheaper than traditional construction?

Modular construction is typically cheaper and quicker to implement than traditional construction methods. The cost of building a module depends on a number of factors, including specification and design requirements. Modular construction can also provide cost savings through more efficient management of materials and the manufacturing process.

-

What are the dimensions of the modules?

There is no standard dimension with Unihouse production. The technology is flexible and adaptable to individual project needs. Up to now, the width of the module has varied between 1.8 and 5.4 m, and the length has ranged from approximately 3 to 16.5 m. The module height for a building with a flat roof oscillates between 3 and 3.6 m, depending on the storey.

-

Are there standard dimensions for the modules?

There are no standard dimensions for modules in Unihouse technology. This is determined on a case-by-case basis. There can be modules of different dimensions in one project.

-

What fire class do the modules meet?

Depending on your needs, it is possible to achieve different fire performance. Unihouse is certified for many partitions and classes. Some of the solutions are based on research that Unihouse has commissioned from the ITB laboratory, and some are based on solutions from well-known manufacturers of individual building materials. Unihouse has solutions for REI 90 and even REI 120 fire resistance.

-

What are the thermal performance characteristics of Unihouse modular buildings?

Timber construction offers the potential for better thermal performance than traditional construction, while maintaining a more liveable microclimate inside the building. Unihouse adapts to the market, customer guidelines and the specific project. As standard, the basic partitions have higher parameters than required by Polish law.

It is possible to achieve the parameters of a passive or even low-energy building, as demonstrated by the Research and Development Building erected by Unihouse at 5 Rejonowa Street in Bielsko - check out the first zero-energy building from Unihouse.

-

What conditions must a plot of land meet in order for a modular building to be built on it?

The plot must meet the conditions as for traditional construction in order for a modular building to be constructed by Unihouse:

- Building requirements. The plot should be classified as a building site and meet local building regulations.

- Adaptation to ground conditions. Unihouse modular buildings can be erected on various types of land, including challenging land.

- Provision of suitable infrastructure. At the production stage, each module is equipped with the necessary utilities, so the plot must allow for connection to utilities such as electricity and sewerage.

- Preparing the foundation. Prior to the installation of the modules, it is necessary to prepare the foundations or other foundation in accordance with the design specifications.

- Possibility of access to the plot for large-scale transport and a crane for assembly.

It is also advisable to consult the local authorities for details of the requirements and procedures for constructing a modular building on the chosen plot.

-

What foundations are needed for the modules?

Foundations for modular buildings are usually traditional footings or foundation slabs with the utilities discharged, on which the modules are then placed. Concrete foundations are adapted to the ground conditions and design loads. A timber building is lighter than a traditional building, so foundations for modules can be cheaper than for a traditional building. This is especially important in difficult areas such as post-mining areas with non-bearing ground layers requiring piles. It is important that the foundations are properly prepared and coordinated with the module manufacturer. Modular buildings also often use foundation slabs, which provide even load distribution and are quicker to construct than traditional foundations.

-

What is the difference between modular construction and traditional construction?

-

- Construction process. Modular construction involves manufacturing the modules in a factory, which is quicker and less dependent on weather conditions, whereas traditional construction takes place on site.

- Lead time. Modular buildings are usually ready in a shorter period of time because factory production allows construction and site preparation work to take place simultaneously.

- Costs. Modular construction can offer lower overall costs due to more efficient materials management and reduced waste.

- Flexibility. Modules can be easily adapted to different needs and requirements, and expanded or modified in the future.

- Sustainability. Modular construction is often more environmentally friendly, as it minimises material waste and allows better control of emissions during production.

These differences make modular construction an attractive alternative to traditional methods, especially for projects requiring rapid delivery and flexibility.

-

-

Where to learn modular construction?

You are cordially invited to Unihouse for apprenticeships and work placements where you can learn modular construction. We offer you the opportunity to gain practical knowledge and experience in a rapidly growing industry. We organise training for architects and others interested in modular construction. We cooperate with many schools, including the Bialystok University of Technology, where our representatives often perform.