Among the key trends in construction, we can highlight low emissions, minimizing environmental impact, and energy efficiency. These requirements are met by technologies that include frame construction. What distinguishes frame buildings, and what are their advantages?

What Are Frame Buildings?

As the name suggests, an integral part of a frame building is its frame. This frame can be entirely constructed on-site or prefabricated components can be transported to the construction site and then assembled. As a result, the primary difference between frame buildings and those built using traditional technology is their construction method—visually, they may not always be distinguishable.

Both on-site frame buildings and prefabricated frame construction are gaining popularity for several reasons. This proven technology shortens construction time, addresses climate change challenges, and provides comfortable conditions for building occupants.

Frame vs. Traditional Buildings – Key Differences

From a technical perspective, the key difference between frame and traditional construction is the load-bearing element. In frame buildings, the frame is load-bearing—without the need for solid walls. In traditional buildings, the walls themselves provide structural support. However, there are more differences between these two types of buildings:

-

Weight: Frame buildings are lighter than brick buildings. This is significant when the ground's load-bearing capacity is not optimal.

-

Energy Efficiency: Frame buildings perform better in terms of insulation. Their construction allows for superior thermal insulation, as the insulation layer is inside the walls rather than outside.

-

Eco-Friendliness: If a wooden frame is used, the materials in frame construction are more environmentally friendly and help reduce CO₂ emissions.

-

Construction Time: Traditional construction follows a fixed sequence of steps, many of which cannot be expedited. Frame technology offers more flexibility in this regard.

Advantages of Frame Buildings

One of the reasons frame buildings are growing in popularity is their numerous advantages. These benefits are often linked to the material used for the frame—wood is increasingly replacing reinforced concrete and steel. Why?

Wood is renewable and has excellent thermal, acoustic, and structural properties. Using wood helps reduce CO₂ emissions, and indoor spaces benefit from a healthier microclimate. Additionally, wooden frames are highly versatile—one notable application is modular construction.

What Is Modular Construction?

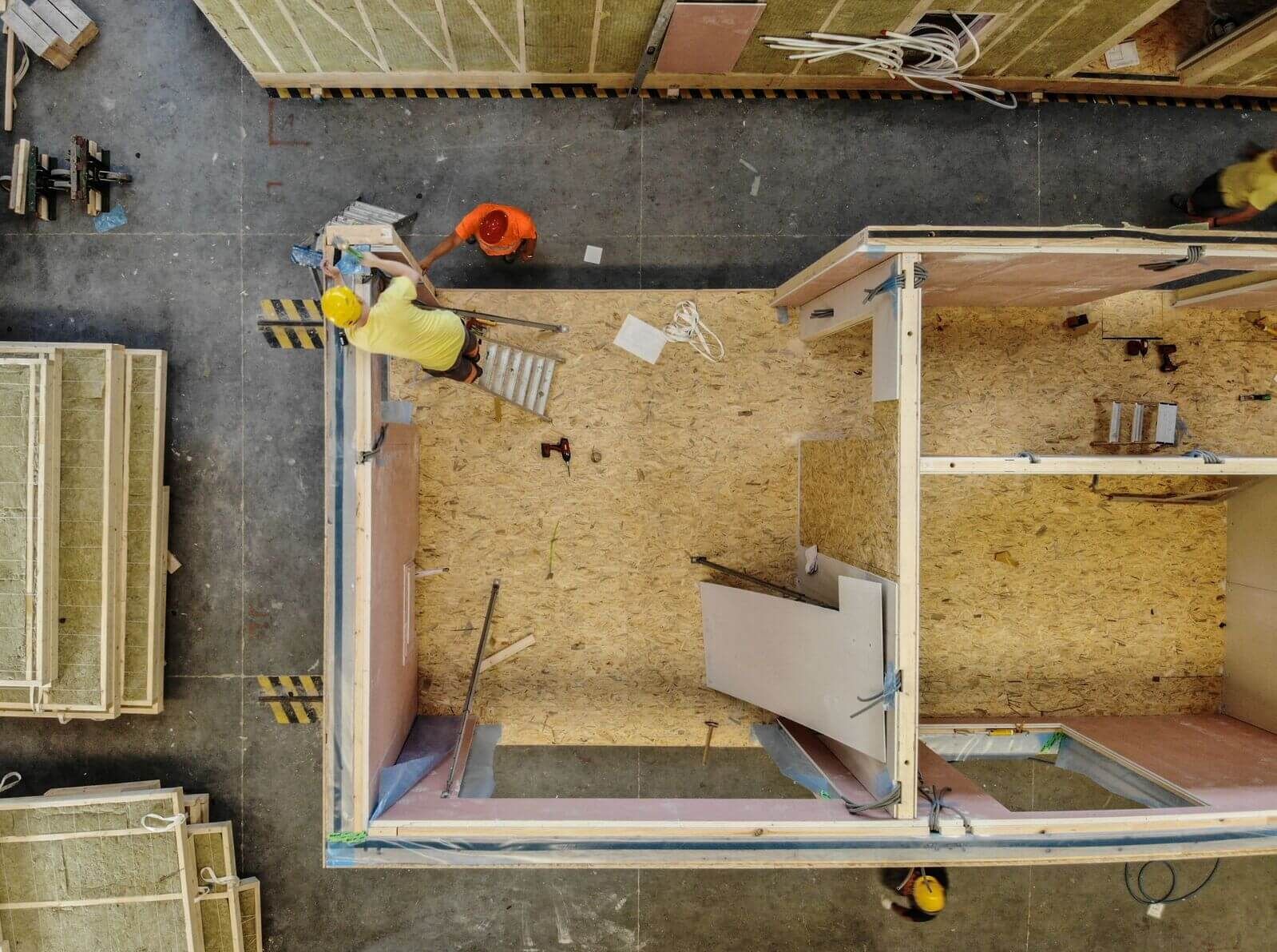

Wood-framed modular construction combines two innovative technologies—prefabricated modules are produced in highly automated factories, and their wooden frames ensure durability, meet fire safety standards, and are eco-friendly.

How to Plan the Construction of a Frame Building?

Frame buildings are constructed in phases. The first step is creating a design—the investor presents their concept, which is then developed into architectural documentation. Necessary permits must also be obtained before work begins. The next stages of construction include:

-

Foundation Work: A traditional foundation is required to support the wooden frame or assemble the modules.

-

Frame Assembly: This step is usually combined with high-efficiency insulation, reducing the building's heat demand.

-

Roof Installation, Windows, and Doors: At this stage, the building takes shape but is not yet ready for use.

-

Utility Installation: If built using modular technology, utilities are installed in the factory before assembly.

-

Exterior and Interior Finishing: The interior is completed, including flooring and tile installation. In modular construction, this is done in the factory before delivery.

-

Furnishing the Spaces: This is the final phase. In modular construction, the modules can be pre-furnished to meet the investor's expectations.

-

Building Approval: The final step involves official procedures before the building can be occupied.

Examples of Frame Buildings in Use

Frame construction is used not only for office towers, production halls, and warehouses but also for single-family homes. Today, this technology is also used for multi-family buildings. At the same time, modular social housing, modular preschools, modular hotels, and student dormitories are being built—each featuring a wooden load-bearing frame in every module.

Given the demands of modern construction, frame and modular technologies are becoming increasingly popular. The advantages of wood, combined with lower long-term maintenance costs, make frame and modular construction attractive choices for investors.