From design to completion – how does the construction of a modular hotel proceed? See it on the example of the Nardobakken and Persaunet student houses,

The accommodation market is changing faster than ever before. Investors expect solutions that combine modern architecture, user comfort, and maximum efficiency of the construction process. For many of them, a key question arises: how to create a facility in a short time that will be functional, durable, and economical to maintain?

The answer is modular construction – a technology that transfers most of the work from the construction site to the factory, thereby shortening the implementation time and minimizing risks. At Unihouse, this model of operation is an everyday reality. For years, we have been carrying out projects throughout Europe, including in the demanding conditions of Scandinavia.

One of the best examples of how the process looks “from sketch to finished building” are the student houses in Trondheim –– Nardobakken i Persaunet. though formally they are student dormitories, their standard, functionality, and method of implementation perfectly show how the construction of a modular hotel proceeds.

The starting point – what did the investor expect?

Trondheim is one of Norway’s most important academic cities. The growing number of students created a need for a modern accommodation base that would ensure long-term comfort and meet strict building standards.

There were several challenges:

- Time – the facilities had to be completed quickly to meet demand.

- Ecology – it was necessary to use solutions compliant with the DNSH principle and sustainable construction standards.

- Safety and comfort – the buildings had to meet high acoustic, thermal, and fire safety requirements.

- Quality – the investor expected facilities that would be durable, aesthetic, and ready for use on the day of completion.

- From the perspective of traditional construction, these conditions might seem difficult to reconcile. However, modular prefabrication turned out to be the perfect solution.

- Design – from sketch to digital building model

Every investment starts with an idea. In the case of the Trondheim student houses, the key was to combine functionality and resident comfort with the technical requirements of the Norwegian market.

The project was supervised by the Unihouse design team, which developed a solution perfectly tailored to the investor’s needs. Designing modular buildings requires precision and excellent coordination. That is why at Unihouse every building is first created as a detailed digital model.

It’s more than a traditional technical drawing – it’s a full virtual mock-up designed in BIM (Building Information Modeling) technology, which allows checking every detail before production begins. This makes it possible to quickly detect potential conflicts, optimize the installation layout, and plan all finishing elements.

“At Unihouse, we combine creativity with solid engineering knowledge. Our specialists also successfully adapt traditional projects to modular technology, offering investors optimal solutions. We work using digital modeling technology, which enables precise and efficient design,” emphasizes Head of the Design Department.

Thanks to this approach, the project becomes a solid foundation for the entire process – and what was planned on the screen is later perfectly reflected in the actual building.

The factory – the heart of modular construction

The next step is to transfer the project to the factory in Bielsk Podlaski. There, on a production area of 19,000 m², modules are created and then transported to the construction site.

Prefabrication means that most construction work takes place under a roof, in controlled conditions, away from the whims of the weather. Walls, ceilings, and floors are manufactured according to design documentation and then assembled into complete modules.

At the factory stage, electrical, heating, and ventilation installations are already installed, as well as furniture and finishing elements. In practice, this means that fully equipped building segments are delivered to the construction site. On-site, only cranes and assembly teams are needed to put together a full-scale building within a few days.

A process that would take many months in traditional construction takes only a fraction of that time with modular technology.

Assembly – a building completed in a few weeks

The moment the modules leave the factory and arrive at the construction site marks a real breakthrough in the entire process. That’s when the investor and future users can see how the design evolves from a sketch and digital model into a tangible structure.

In Trondheim, both at th Nardobakken, and Persaunet, student houses, assembly progressed rapidly. Cranes lifted the finished modules and placed them on top of each other like building blocks, while specialized teams connected them into a single building form.

A process that would take many months in traditional construction was shortened here to just a few weeks.

The final result – ready student houses as an example of modern modular construction

Akademiki Nardobakken w Trondheim

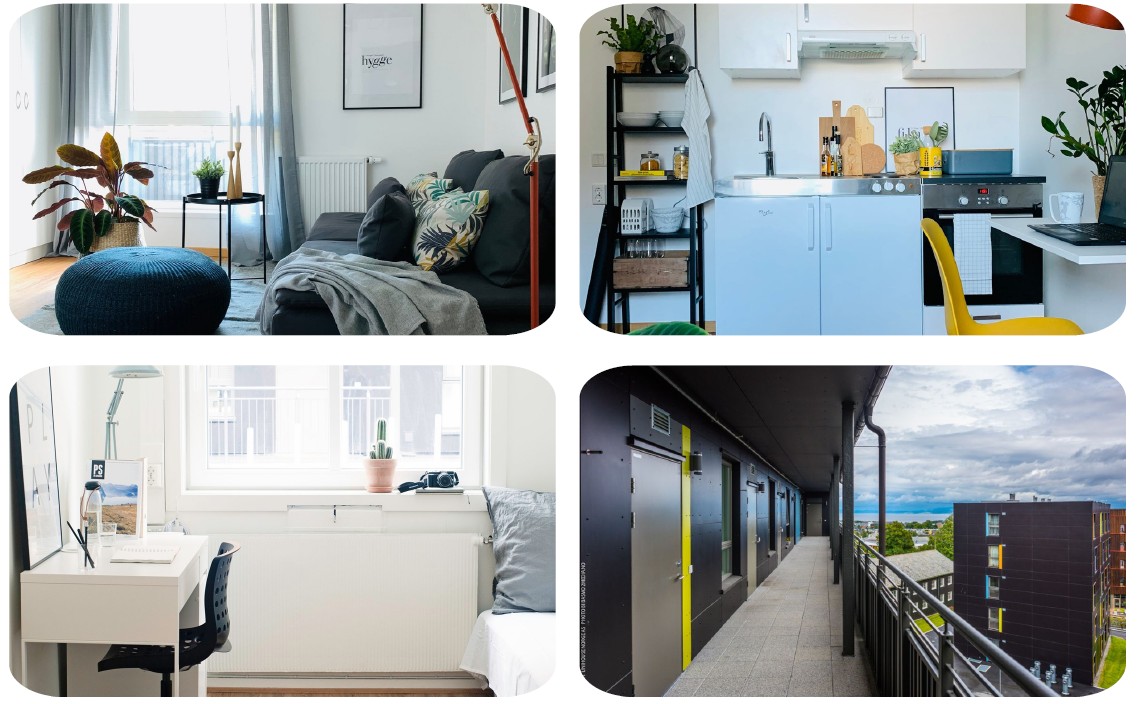

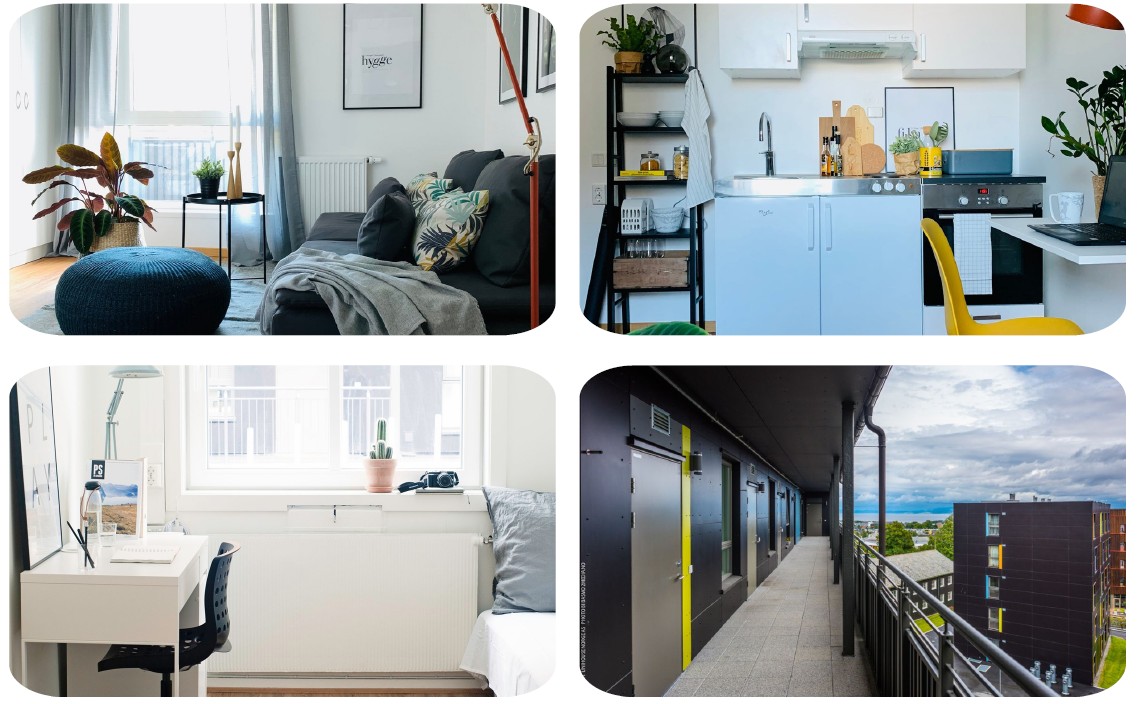

This project created a 4- and 5-story complex with a total area of over 5,275 m², consisting of 176 modules. It includes 256 fully equipped rooms for students. The building was designed to ensure tenant comfort and privacy while meeting the strict requirements of Norwegian construction law.

Akademiki Persaunet w Trondheim

The second investment is a 4,802 m² facility built from 127 modules. It contains 89 rooms which – as in Nardobakken – were ready for use upon completion. This means students could move in immediately, without any additional finishing or adaptation work.

In both projects, the modules left the factory fully finished, and on-site in Trondheim they only needed to be assembled and fine-tuned. The result? Fully operational complexes completed in a record short time

What did the investor gain by choosing Unihouse modular technology?

For the investor, choosing modular technology meant not only fast project completion but also certainty and safety at every stage. Each element of the building was first designed in a digital BIM model and then produced in the factory under strict quality control. This made the entire process predictable, and the final result matched the plan.

The key benefits achieved were:

- Full control and predictability of the process – no weather delays, execution errors, or material shortages.

- Shortened implementation time – instead of many months of construction, the finished facilities were built in a fraction of the time.

- Sustainable approach – wooden modular structures and energy efficiency increased the environmental and image value of the investment.

Why Unihouse? Because here, it’s about more than construction

The Trondheim student houses clearly show that modular construction is no longer just an alternative to traditional methods – it’s a solution that truly changes the rules of the game.

Nardobakken and Persaunet were built quickly, within a predictable budget, and from the very beginning offered comfort that meets the expectations of even the most demanding users.

The secret lies in a comprehensive approach. Unihouse not only designs and manufactures modules but also takes full responsibility for the entire process – from the first concept, through the digital building model, to on-site assembly and turnkey delivery.

Thanks to this, the investor gets a partner who acts as architect, manufacturer, and general contractor all in one.

It’s no coincidence that in Scandinavia – one of the most demanding markets in Europe – Unihouse continues to deliver prestigious projects. Quality certificates, compliance with strict environmental and safety standards, and years of experience make us a reliable, proven, and future-oriented choice.

Modular construction means speed, control, and innovation combined.

If you are thinking about a hotel, student residence, or other accommodation facility that will be built faster, cheaper to operate, and more environmentally friendly – Unihouse is the partner you are looking for.

Information

© 2022 UNIHOUSE SA All rights reserved. | Design Sensorama